Galvanized Steel Grating Applications in Construction, Design, Sewage Treatment, and Engineering

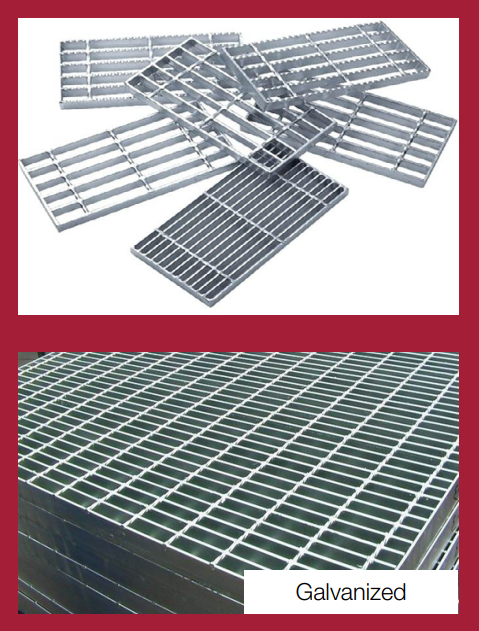

Galvanized grating, also called galvanized steel grating or galvanized steel bar grating, refers to the steel bar grating made of mild carbon steel through hot dipped galvanized surface treatment.

Mild carbon steel provides an economical, high strength for uses in most industrial and commercial applications. And hot dipped galvanized surface treatment supplies excellent corrosion resistance performance for durability.

Steel grating is available in various material, such as stainless steel, aluminum, and galvanized steel. Among them, the galvanized steel grating is the most cost effective and economical type with long service life and high load. And it is the most widely used in both industrial, commercial and residential applications.

- Product Details

- Technical Specification

Galvanized grating.

Serrated galvanized grating.

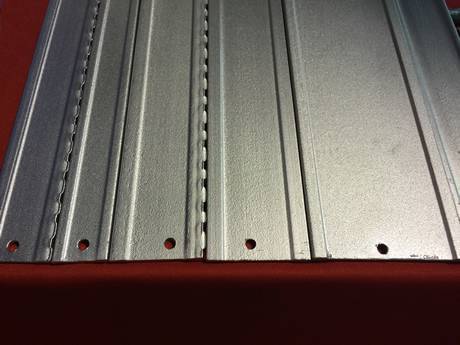

Bearing bars of galvanized steel grating.

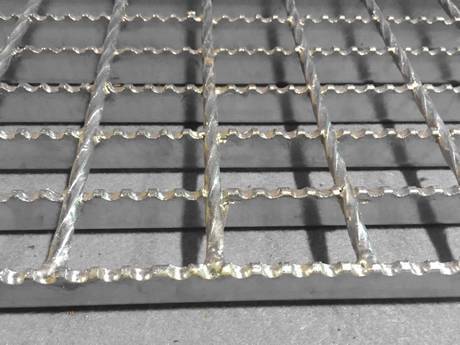

Twisted bars of galvanized steel grating.

Technology

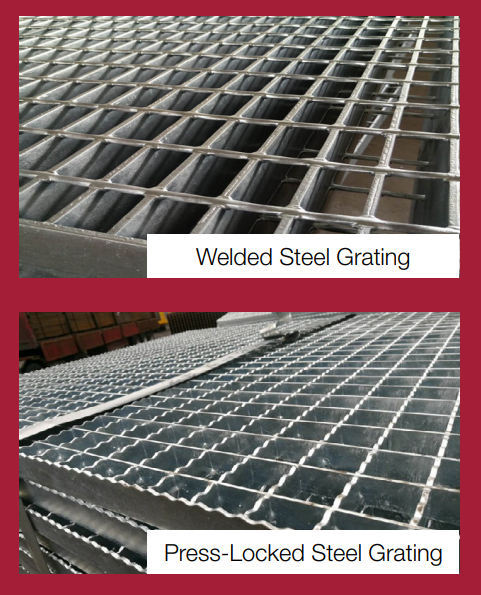

Welded galvanized grating. The cross bars are welded onto bearing bars with the high pressure resistance welding machine and then cutting, banding, surface treatment.

Press-locked galvanized grating. The cross bars are pressure locked onto the bearing bars with grooving and then welding and hot dipped galvanizing.

Features & Characteristics

High strength. The strength and the toughness are much higher than cast iron. Can be used for terminals, airport and other large-span and heavy loading condition.

Hot-dip galvanized treatment. Good rust-proof property, maintenance-free replacement.

Anti-theft design. The cover and the frame is joint with hinge offering security, safety and open convenience.

Savings investments. Large-span. Less lost for heavy load compared with cast iron products. Cost can be saved for the risk of being stolen or crushing one if cast iron is uses.

Aesthetic outlook. Simple lines and silver appearance meeting the modern trend.

The best drainage. Leakage area of 83.3 percent, more than twice of cast iron products.

Applications

Galvanized grating are designed and manufactured for various industrial and civil constructions in city road, gardens, yard, airport, railway and industrial engineering.

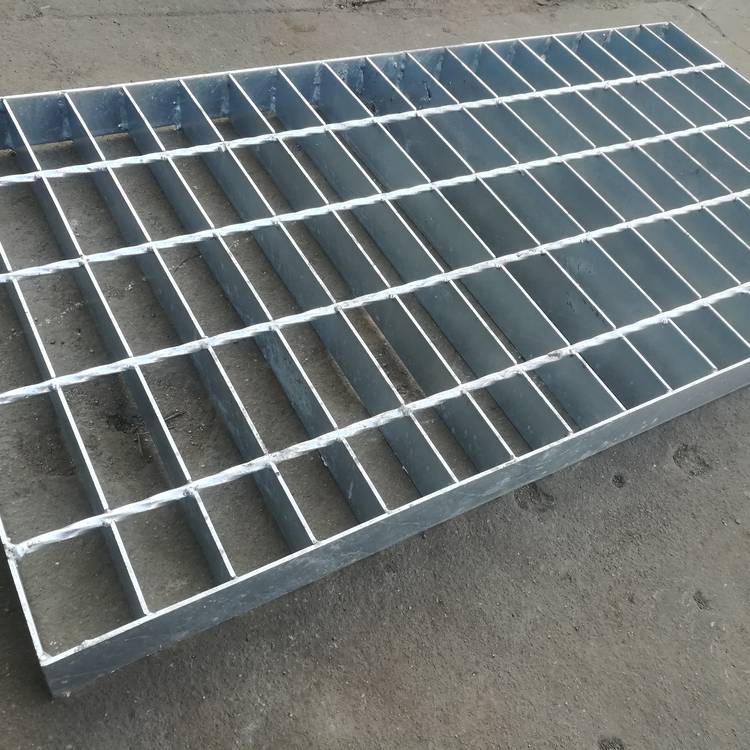

Hot dip galvanized steel grating is the best choice for steel platforms in airports. Grating with 30 × 3 mm thick load bearing bars with a pitch of 30 mm and traverse bars at 50 mm or 100 mm is the suitable one.

Steel grating, with robust design and spanning abilities, is very strong and safe for the support of floors and elevated walkway. It can be used for ceiling, interior decoration, platform aisle, ventilation windows, (Wells), advertising plaque and other construction.

Widely used in the petrochemical industry, power plants, waterworks, sewage treatment plants, municipal works, sanitation projects in areas such as platforms, corridors, bridge, ditch cover, covers, ladders, fences, rails, and so on.

Anping Lingguan Metal Mesh Co., Ltd. is a reputable company that emphasizes quality, offering competitive prices and guaranteed quality. Here are the details:

Features and Applications of Steel Grating:

High Strength, Lightweight Structure: The robust welded mesh structure provides high load-bearing capacity, a lightweight design, and ease of installation.

Aesthetic Appearance, Durability: Hot-dip galvanizing treatment ensures excellent corrosion resistance and a glossy, attractive surface.

Ventilation, Lighting, Heat Dissipation, Non-slip, Non-explosive: The design allows for good ventilation, natural lighting, heat dissipation, and non-slip properties, while preventing accumulation of debris.

Wide Applications: Commonly used in platforms, walkways, bridges, trench covers, manhole covers, ladders, fences, and guardrails in industries such as petrochemical, power plants, water treatment plants, sewage treatment plants, municipal engineering, and sanitation projects.

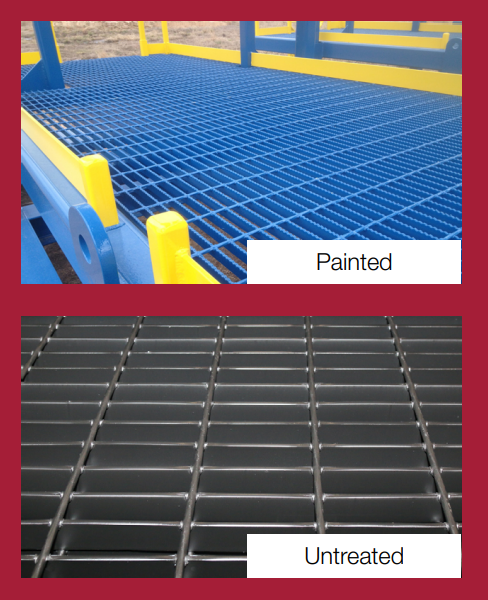

Surface Treatments:

Hot-dip galvanizing

Painting

Cold galvanizing

Standards:

China: YB/T4001-1998

USA: ANSI/NAAMM9MBG531-88

UK: BS4592-1987

Common Specifications:

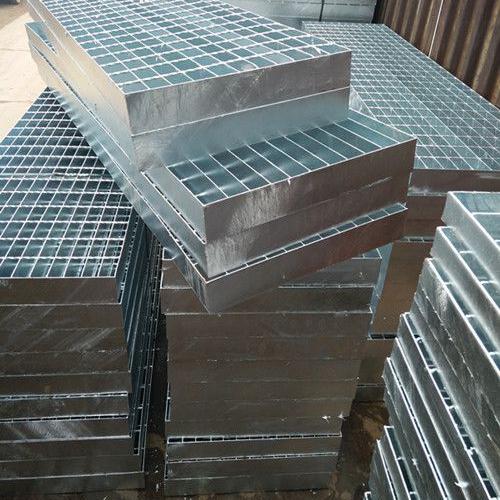

30×100 mm

30×50 mm

40×100 mm

40×50 mm

30×76 mm

Standard plate thicknesses include 2 mm, 3 mm, 4 mm, 5 mm, and 8 mm. Custom specifications are available upon request.

Materials:

Manufactured from carbon steel, with hot-dip galvanizing treatment to prevent oxidation. Hot-dip galvanizing is the most commonly used method.

For more information, please contact us.

Painted Steel Grating

Painted Steel Grating  High-Quality Stainless Steel G...

High-Quality Stainless Steel G...  Galvanized Steel Grating Appli...

Galvanized Steel Grating Appli...  Gully Grating Steel Cover

Gully Grating Steel Cover  Stair Tread Plates

Stair Tread Plates  lrregular Steel Grating

lrregular Steel Grating  Heavy Duty Steel Grating

Heavy Duty Steel Grating  Plug-In Steel Grating

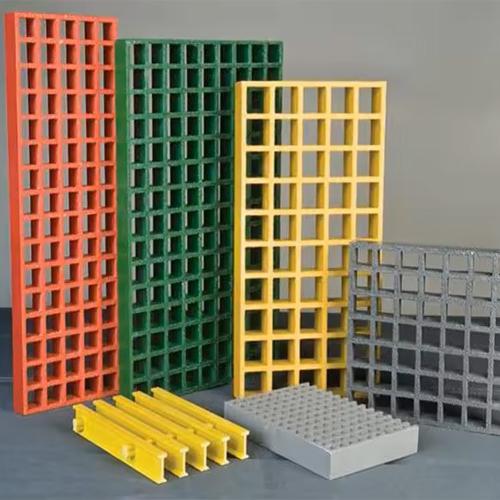

Plug-In Steel Grating  High-Quality Fiberglass Gratin...

High-Quality Fiberglass Gratin...