Stair Tread Plates

Explore our high-quality stair tread plates, designed for safety and durability. Our steel stair treads offer anti-slip features, corrosion resistance, and custom options for industrial and commercial applications. Perfect for secure, long-lasting stairways.

Stair Tread Plates Overview

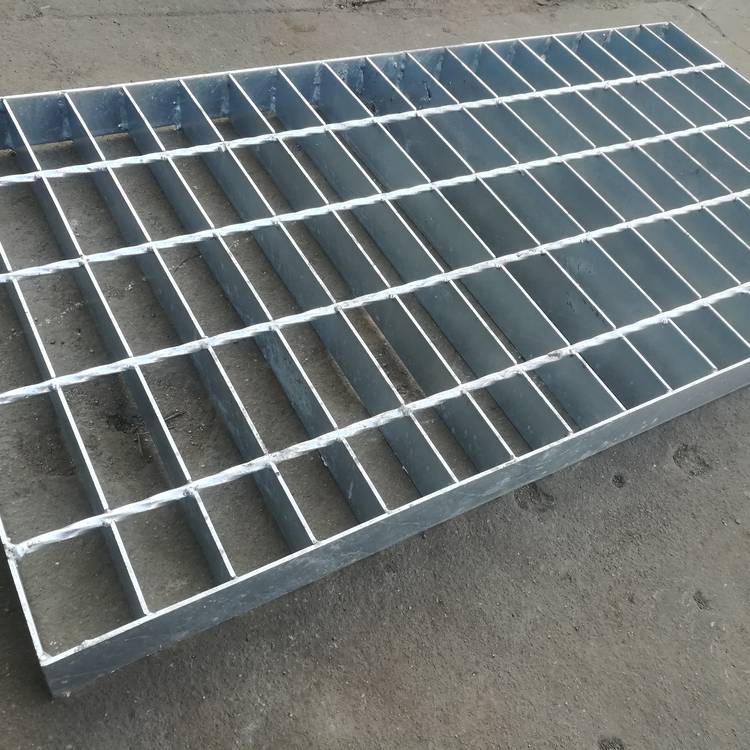

Material Composition:

Stair tread plates are made from steel grating, a product formed by welding flat steel bars arranged in a grid pattern, with specific spacing between the bars. These plates are typically treated with hot-dip galvanizing or electro-galvanizing for corrosion resistance.

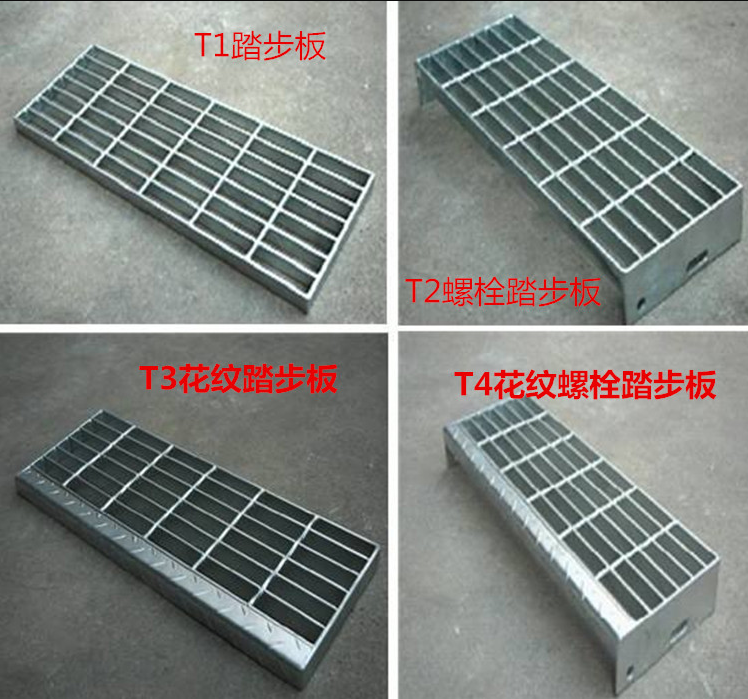

Types of Stair Tread Plates

Installation Types:

Welded Tread Plates: Directly welded onto the support structure, typically used for permanent installations.

Bolt-Fixed Tread Plates: These plates have additional side plates (65x5mm flat steel) and are secured using bolts, offering ease of removal and reusability.

Anti-Slip Types:

With Front Guard Plate: Features an anti-slip surface, including pattern plates or steel bars.

Without Front Guard Plate: Simple tread plates without additional anti-slip features.

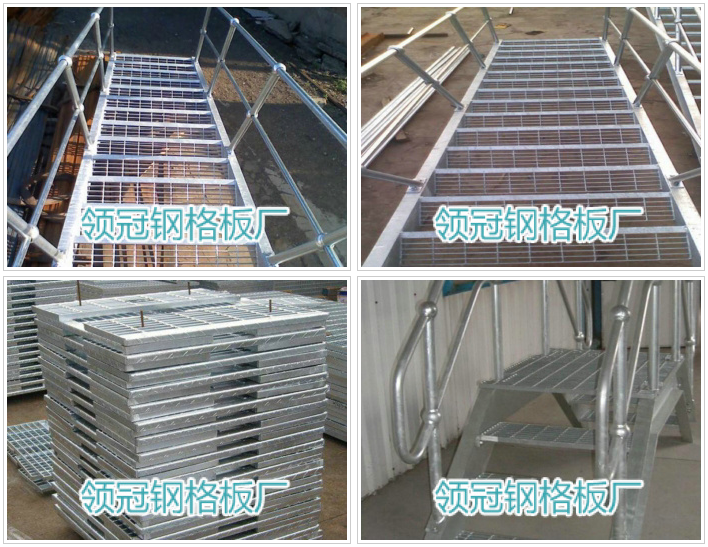

Applications of Stair Tread Plates

Used in various environments, such as:

Industrial platforms

Stair treads

Guardrails

Flooring for passages, bridges, and elevated platforms

Drain covers, manhole covers

Highway and railway barriers

Fences for schools, factories, sports fields, gardens, and residential areas

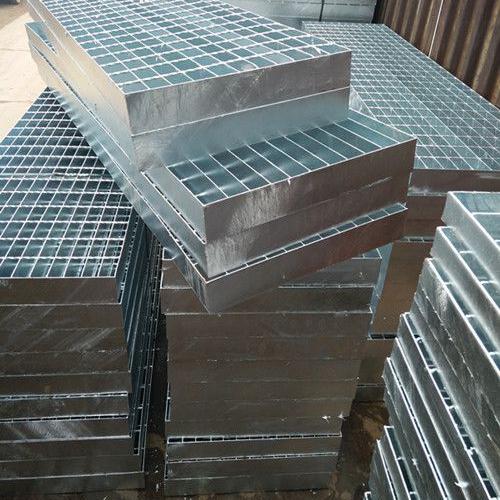

Common Specifications and Sizes

General Sizes:

T1 to T4 Series: Step sizes range from 125mm to 305mm in width, with varying step spacing (30mm, 40mm, 60mm).

Modular Widths: To optimize for cost, recommended widths are in multiples of 100mm (e.g., 125, 155, 185mm).

Tread Plate Series:

T1: Welded, basic load-bearing steel tread.

T2: Bolt-fixed, with side plates.

T3: Features front guard plate for anti-slip.

T4: Bolt-fixed with front guard plate.

Manufacturing and Quality Assurance

Our stair tread plates are manufactured with strict quality controls. We ensure:

Welding Quality: Strong welds on guard plates and edges.

Size Tolerances: Length tolerance within ±3mm, width tolerance within ±3mm.

Surface Treatment: Hot-dip galvanizing for corrosion resistance, providing longevity.

Custom Manufacturing Options

We offer tailored solutions with no minimum order quantity. Whether you need a few pieces or bulk orders, we can accommodate. Delivery timelines are strictly adhered to, ensuring timely service.

Installation Methods

Welded Fixing: Permanent installation but less flexible for maintenance.

Bolt-Fixed: Easier to install, remove, and reassemble, suitable for environments requiring regular inspection.

Product Features and Quality

Our stair tread plates are highly regarded for:

Uniform grid spacing

Solid welding points

Attractive and practical design

Easy to install with either bolts or welding

Common Materials and Standards

Our hot-dip galvanized tread plates conform to various standards, including:

China: YB/T4001-1998

USA: ANSI/NAAMM9MBG531-88

UK: BS4592-1987

We manufacture high-quality, durable stair tread plates with precise specifications and offer competitive pricing by eliminating middlemen. If you're looking for custom or standard tread plates, contact us for a reliable solution.

Painted Steel Grating

Painted Steel Grating  High-Quality Stainless Steel G...

High-Quality Stainless Steel G...  Galvanized Steel Grating Appli...

Galvanized Steel Grating Appli...  Gully Grating Steel Cover

Gully Grating Steel Cover  Stair Tread Plates

Stair Tread Plates  lrregular Steel Grating

lrregular Steel Grating  Heavy Duty Steel Grating

Heavy Duty Steel Grating  Plug-In Steel Grating

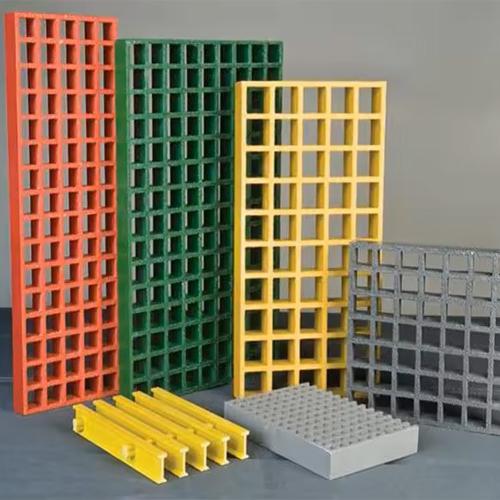

Plug-In Steel Grating  High-Quality Fiberglass Gratin...

High-Quality Fiberglass Gratin...